Byculla, Mumbai, Maharashtra

- GST NO. : 27AAZFA9533B1Z5

View Mobile Number

Scaling & Chipping Items

Leading Wholesaler, Retailer and Trader of Impa 370309 Brass Sounding Rod – 1 Meter Measuring Stick for Liquid Depth Reading, Impa 590382 Pneumatic Single Piston Scaler, Impa 590461/590462/590463/590464 Pneumatic Needle Scalers Air Tools for Rust, Scale & Paint, Impa 590531 Pneumatic Flux Chipper – Air Tool, Impa 591201 591203 Electric Needle Scaler, Impa 591206 Electric Descaling Chain Machine KP2000E – 200mm High-Speed Rust & Paint Removal Tool, Impa 591209 Spare Chain Drum for Electric Descaling Machine KP2000E – Replacement Drum Unit, Impa 591212 Electric Descaling Chain Machine KP1200E – High-Speed Rust (440V, 120mm), Impa 591237 Spare Chain Drum for Electric Descaling Machine KP1200E & KP400 – Replacement Part, Impa 591661 Pneumatic Piston Pump – High-Efficiency Drum Pump for Lubrication & Viscous Liquid, Impa Electric Angle Grinder Marine, Impa Oil Spill Kit, Impa trolley-mounted Pneumatic Scaling Machine and Viking Johnson Type Flexible Pipe Coupling for Leak-Proof Marine from Mumbai.

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Code | 370309 |

| Material | Brass (non-sparking) |

| Length | 1 meter |

| Graduation Type | Metric scale (mm or cm) |

| Surface Finishing | Smooth, corrosion-resistant polish |

| Use Cases | Oil, water, chemical, ballast tanks |

| Marine Suitability | Yes – used across vessels and tankers |

- \r\n

- \r\n

🔩 Machined from Solid Brass – Non-corrosive, rustproof, and highly durable for marine use.

\r\n \r\n - \r\n

📏 Used for Manual Depth Sounding – Measures oil, water, or chemical levels in tanks and sumps.

\r\n \r\n - \r\n

📐 Precisely Calibrated Length (1 Meter) – Offers accuracy for shipboard tank and drum inspections.

\r\n \r\n - \r\n

🧱 Flat-Edged Profile – Prevents rolling and ensures consistent contact with tank bottom.

\r\n \r\n - \r\n

🧲 Non-Sparking Composition – Safe for use in explosive or fuel-rich atmospheres.

\r\n \r\n - \r\n

🔧 Simple, Mechanical Tool – No moving parts, no maintenance, always ready to use.

\r\n \r\n - \r\n

🧪 Chemical-Resistant Surface – Stands up to hydrocarbons, water, sludge, and acids.

\r\n \r\n - \r\n

📦 Compact & Easy to Store – Fits in any toolbox, sound locker, or deck cabinet.

\r\n \r\n - \r\n

🔩 Clearly Etched Graduations – Millimeter or centimeter markings ensure quick readings.

\r\n \r\n - \r\n

🧰 Common for Fuel Tanks, Oil Drums & Ballast Compartments – Universal use across maritime operations.

\r\n \r\n - \r\n

🛠️ Ideal for Rapid Spot-Checks – Use during emergency or routine checks without setup.

\r\n \r\n - \r\n

🌊 Suitable for Fresh, Brackish, or Saltwater Tanks – Fully marine-environment compliant.

\r\n \r\n - \r\n

🔁 Reusable for Thousands of Readings – Long life, minimal wear with proper cleaning.

\r\n \r\n - \r\n

✅ IMO/SOLAS Compliant Measurement Tool – Approved as part of engine room sounding equipment.

\r\n \r\n

\r\n

- \r\n

- \r\n

💼 Used on Deck, in Engine Room, and for Fuel Inspection – Key tool for chief engineers and bunkering officers.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Application | Removal Of Rust,Old Paint,Coatings |

| IMPA Code (Tool) | 590382 |

| IMPA Code (Spare Piston) | 590386 |

| Operation Type | Pneumatic – single piston |

| Construction | Industrial-grade, corrosion-resistant body |

| Use Environment | Marine, shipyards, offshore, and industrial sectors |

| Maintenance Support | Replaceable piston with spare available |

)

\r\n- \r\n

- \r\n

💨 Compressed-Air Operated Scaler – Utilizes pneumatic force to chip away rust, old paint, and coatings from metal surfaces.

\r\n \r\n - \r\n

🔩 Single Piston Design – Provides powerful, direct chiseling action for aggressive material removal.

\r\n \r\n - \r\n

🔧 Spare Piston Available (IMPA 590386) – Minimizes downtime and ensures continuous tool availability.

\r\n \r\n - \r\n

🧱 Ideal for Heavy-Duty Surface Prep Tasks – Commonly used on ship hulls, steel decks, and machinery frames.

\r\n \r\n - \r\n

🧰 Compact & Lightweight – Enables easy handling in tight shipyard spaces or overhead work.

\r\n \r\n - \r\n

🔁 Continuous Duty Performance – Designed for long-duration use in industrial and marine applications.

\r\n \r\n - \r\n

🧪 Built from High-Durability Components – Withstands harsh environments and repetitive use.

\r\n \r\n - \r\n

🌊 Marine-Grade Corrosion Resistance – Suitable for shipboard and dockside conditions.

\r\n \r\n - \r\n

🧤 Comfortable Grip for Extended Operation – Reduces hand fatigue during prolonged scaling.

\r\n \r\n - \r\n

🛠️ Easy Maintenance & Piston Replacement – Quick disassembly with minimal tools required.

\r\n \r\n - \r\n

⚙️ Powerful Impact Chiseling – Removes multiple coating layers in fewer passes.

\r\n \r\n - \r\n

🧲 Used in Pre-Painting & Inspection Prep – Ensures clean metal surface for coating adhesion.

\r\n \r\n - \r\n

✅ IMPA-Coded for Procurement Compatibility – Recognized across marine and offshore supply chains.

\r\n \r\n - \r\n

🔧 Versatile for Industrial Repair & Maintenance – Applicable across sectors like shipbuilding, oil & gas, and infrastructure.

\r\n \r\n - \r\n

📦 Tool + Spare Piston Support – Supplied with service-friendly parts support for operational continuity.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Codes | 590461 (JC16) |

| Tool Type | Pneumatic (air-powered) needle scaler |

| Application | Rust, scale, and paint removal on metal surfaces |

| Needle Material | Hardened steel – replaceable and impact-resistant |

| Operation Mechanism | Reciprocating stroke via compressed air |

| Tool Body Construction | Industrial-grade steel/aluminum alloy housing |

| Compatibility` | Suitable for marine, offshore, shipyard, and industrial environments |

ModelIMPA CodeStroke TypeUse CaseNotes

\r\n| JC16 | \r\n590461 | \r\nLight-duty | \r\nConfined spaces, routine maintenance | \r\nLightweight & compact | \r\n

| JT20 | \r\n590462 | \r\nMedium-duty | \r\nGeneral marine and steelwork prep | \r\nAll-purpose tool | \r\n

| JEX24 | \r\n590463 | \r\nHeavy-duty | \r\nHull descaling, tank interiors | \r\nStrong impact force | \r\n

| JEX28/66 | \r\n590464 | \r\nExtra heavy | \r\nLarge surface prep, severe corrosion | \r\nHigh power & longer stroke | \r\n

- \r\n

- \r\n

💨 Air-Powered Surface Preparation Tools – Efficiently remove rust, paint, scale, and marine growth from metal surfaces.

\r\n \r\n - \r\n

🔧 Four Models Available for Varying Applications –

\r\n

• JC16 (IMPA 590461) – Compact and lightweight for confined spaces

• JT20 (IMPA 590462) – Versatile for general marine maintenance

• JEX24 (IMPA 590463) – Heavy-duty performance for ship hulls and plates

• JEX28/66 (IMPA 590464) – Extra power and reach for large surface areas \r\n - \r\n

🧲 Ideal for Marine, Industrial & Construction Use – Commonly used on ships, tanks, cranes, and steel structures.

\r\n \r\n - \r\n

🔩 Equipped with Hardened Steel Needles – Penetrates corrosion layers without damaging base metal.

\r\n \r\n - \r\n

🔄 Reciprocating Stroke Action – Converts air power into rapid needle movement for fast removal.

\r\n \r\n - \r\n

🧱 Ergonomic Design for Operator Comfort – Reduces vibration transmission and hand fatigue.

\r\n \r\n - \r\n

🧰 Compact for Hard-to-Reach Areas – JC16 & JEX24 models especially suitable for confined maintenance zones.

\r\n \r\n - \r\n

💪 Durable Industrial Build Quality – Withstands rugged use in shipyards, ports, and construction sites.

\r\n \r\n - \r\n

⚙️ Easy Maintenance with Replaceable Needle Sets – Ensures long service life and tool efficiency.

\r\n \r\n - \r\n

🔧 Quick-Change Needle Holder System – Allows fast replacement of worn needles without downtime.

\r\n \r\n - \r\n

🌊 Performs in Wet or Oily Environments – Designed for ship deck, hull, and tank maintenance.

\r\n \r\n - \r\n

🔩 Power Output Suited to Application Needs – JT20 and JEX28/66 models offer high-impact power for heavy scaling.

\r\n \r\n - \r\n

📦 Supplied Ready to Use with Standard Needles – Optional needle sets available separately.

\r\n \r\n - \r\n

✅ IMPA Coded for Standardized Procurement – Ensures global marine catalog compatibility.

\r\n \r\n - \r\n

🔁 Versatile for All Surface Preparation Phases – Cleaning, pre-painting, descaling, and rust removal.

\r\n \r\n

| Business Type | Retailer, Trader, Distributor, Importer |

| Application | Removal Of Weld Slag, Flux, Rust, Paint |

| IMPA Code | 590531 (Tool) |

| Tool Type | Pneumatic flux chipper |

| Chisel Width | 25 mm (both bent and straight types) |

| Operation Type | Reciprocating pneumatic impact |

| Material | Heavy-duty steel/aluminum alloy |

| Compatibility | Suitable for marine, offshore, shipyard, and industrial environments |

- \r\n

- \r\n

💨 Air-Powered Chipping Tool – Operates on compressed air to remove welding slag, flux, rust, and paint effectively.

\r\n \r\n - \r\n

🛠️ Includes Interchangeable Chisels – Compatible with both straight and bent chisels for different applications and surface types.

\r\n \r\n - \r\n

🔧 Supplied with:

\r\n

• IMPA 590533 – Bent Chisel (25mm)

• IMPA 590535 – Straight Chisel (25mm) \r\n - \r\n

🔁 Quick-Change Chisel Mechanism – Allows rapid tool changes to increase efficiency during continuous operations.

\r\n \r\n - \r\n

🧲 Compact & Lightweight Design – Easy to maneuver in confined or elevated workspaces such as ship hulls or engine rooms.

\r\n \r\n - \r\n

🧱 Strong Impact Performance – Breaks away hardened flux and scale from metal surfaces with precision.

\r\n \r\n - \r\n

🧪 Durable Industrial Build Quality – Constructed for repeated heavy-duty use in rugged environments.

\r\n \r\n - \r\n

🧰 Ergonomic Handle with Anti-Vibration Grip – Reduces user fatigue during extended operation.

\r\n \r\n - \r\n

🧼 Low Maintenance Pneumatic System – Simple internal mechanism with minimal parts for servicing.

\r\n \r\n - \r\n

🔩 Ideal for Surface Prep Before Rewelding or Painting – Cleans steel plates, weld seams, and corroded edges.

\r\n \r\n - \r\n

🌊 Marine-Grade Corrosion Resistance – Safe for use in shipyards, docks, and offshore repair zones.

\r\n \r\n - \r\n

⚙️ Operates on Standard Ship Air Lines – Compatible with most onboard air systems without modification.

\r\n \r\n - \r\n

✅ IMPA Coded for Procurement Efficiency – Listed for standard marine and industrial catalog sourcing.

\r\n \r\n - \r\n

🔧 Multiple Accessory Options Available – Additional chisels and extensions available upon request.

\r\n \r\n - \r\n

🔋 No Electrical Hazards – Safe for use in flammable or hazardous working areas.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Codes | 591201 (110V), |

| Power Rating | 1100 Watts |

| Voltage Options | 110V and 220V |

| Frequency | 60 Hz |

| Blows Per Minute (BPM) | 3600–4500 BPM |

| Needle Configuration | 23 needles, 3 mm each |

- \r\n

- \r\n

Electric-Powered Needle Scaler – Provides powerful surface preparation without the need for compressed air.

\r\n \r\n - \r\n

🔌 Available in 110V and 220V Models –

\r\n

• 110V: IMPA 591201

• 220V: IMPA 591203 \r\n - \r\n

💥 High Impact Output (3600–4500 BPM) – Efficiently removes rust, paint, and stubborn coatings from steel surfaces.

\r\n \r\n - \r\n

🔄 Rotating Handle with Lockable Positions – Offers flexibility and ergonomic comfort for various angles and surfaces.

\r\n \r\n - \r\n

🧵 Equipped with 23 Hardened Steel Needles (3 mm) – Optimized for aggressive material removal with smooth operation.

\r\n \r\n - \r\n

🧱 Ideal for Marine & Industrial Surface Prep – Commonly used for ship hulls, decks, containers, and heavy machinery.

\r\n \r\n - \r\n

🧲 Robust 1100W Motor – Delivers continuous duty performance in demanding work environments.

\r\n \r\n - \r\n

🧰 Low Maintenance Design – Fewer moving parts and no air compressors reduce operational complexity.

\r\n \r\n - \r\n

🧪 Durable Casing & Heat Protection – Withstands workshop conditions and high-load operation.

\r\n \r\n - \r\n

🧤 Operator-Friendly Grip & Balanced Weight – Reduces fatigue during prolonged use in overhead or vertical work.

\r\n \r\n - \r\n

📦 Supplied Ready to Use with Standard Needle Set – Optional needle replacements available on request.

\r\n \r\n - \r\n

🔧 Precision Control for Surface Cleaning – Suitable for weld preparation, spot cleaning, and paint removal.

\r\n \r\n - \r\n

🌊 Safe for Marine & Shipyard Environments – Performs well in moist and salt-exposed areas.

\r\n \r\n - \r\n

✅ IMPA-Coded for Tender and Supply Compliance – Ensures standardized sourcing across global marine supply chains.

\r\n \r\n

\r\n

- \r\n

- \r\n

🔁 Reliable for Continuous Daily Use – Trusted by fabrication teams, shipwrights, and offshore maintenance crews.

\r\n \r\n

Impa 591206 Electric Descaling Chain Machine KP2000E – 200mm High-Speed Rust & Paint Removal Tool

| Business Type | Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Code | 591206 |

| Model | KP2000E |

| Operation Type | Electric – 3-phase, 380V/440V, 60 Hz |

| Cutting Width | 200 mm |

| Impact Rate | 220,000 blows per minute |

| Protective Feature | Dust-proof cover |

| Use Environments | Marine, shipyard, industrial |

- \r\n

- \r\n

High-Speed Chain Descaler – Engineered to remove hard coatings, thick rust, and old paint from flat metal surfaces.

\r\n \r\n - \r\n

Delivers 220,000 Blows Per Minute – Offers ultra-fast impact performance for rapid descaling.

\r\n \r\n - \r\n

Wide 200 mm Cutting Width – Covers more area per pass, reducing job time and operator fatigue.

\r\n \r\n - \r\n

Powered by 380V/440V, 3-Phase, 60 Hz System – Suitable for marine and industrial-grade power supply.

\r\n \r\n - \r\n

Dust-Proof Protective Cover – Shields internal components while containing surface debris during operation.

\r\n \r\n - \r\n

Ideal for Spot Scaling and Medium-Sized Flat Surfaces – Perfect for decks, hatch covers, and tank interiors.

\r\n \r\n - \r\n

Chain Link Impact Head – Conforms to surface contours and avoids surface gouging.

\r\n \r\n - \r\n

Constructed for Heavy-Duty Use – Withstands rugged conditions in shipyards and offshore environments.

\r\n \r\n - \r\n

Reduced Operator Vibration – Built with vibration control features to enhance user safety and comfort.

\r\n \r\n - \r\n

Fast Pre-Coating Surface Prep – Ideal for preparing metal before repainting, welding, or inspection.

\r\n \r\n - \r\n

Consistent High-Output Operation – Designed for long-duration use without overheating or drop in performance.

\r\n \r\n - \r\n

Low Maintenance Requirements – Simple design with service-friendly access to parts.

\r\n \r\n - \r\n

Compatible with Replaceable Chain Drums – Supports quick replacement for continuous work.

\r\n \r\n - \r\n

Safe for Use in Marine and Industrial Zones – Corrosion-resistant and electrically secure.

\r\n \r\n - \r\n

IMPA Coded for Standardized Procurement – Easily integrated into marine and offshore supply chains.

\r\n \r\n

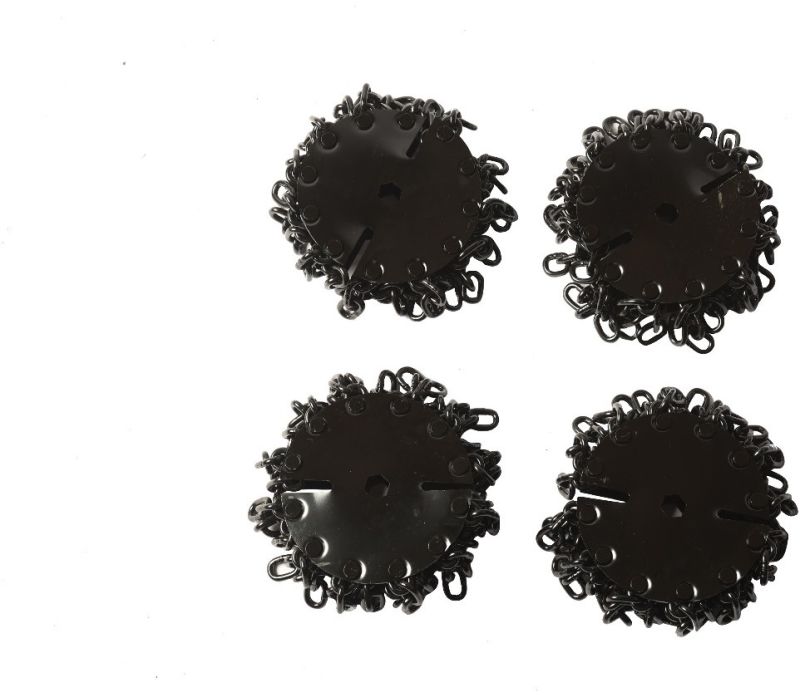

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Material | High-strength steel/alloy with corrosion-resistant finish |

| IMPA Code | 591209 |

| Function | Replacement chain drum for high-speed descaling |

| Cutting Width Support | 200 mm |

| Environment Suitability | Marine, offshore, industrial surface preparation tasks |

- \r\n

- \r\n

Official Replacement Chain Drum – Specifically designed for compatibility with KP2000E descaling machine.

\r\n \r\n - \r\n

Ensures Continuous Performance – Allows uninterrupted operation during maintenance or breakdown.

\r\n \r\n - \r\n

Engineered for High-Speed Impact (220,000 BPM) – Maintains structural integrity during intense surface preparation.

\r\n \r\n - \r\n

Constructed from Heavy-Duty Steel or Alloy – Withstands abrasion from rust, paint, and surface debris.

\r\n \r\n - \r\n

Quick Installation & Removal – Enables tool-free or minimal-tool replacement on-site.

\r\n \r\n - \r\n

Supports 200 mm Cutting Width Output – Maintains original machine performance and surface coverage.

\r\n \r\n - \r\n

Ideal for Marine & Industrial Descaling Tasks – Trusted in shipyards, docks, and offshore platforms.

\r\n \r\n - \r\n

Compatible with KP2000E Series Only – Precision-fit design prevents operational mismatch.

\r\n \r\n - \r\n

Corrosion-Resistant Finish – Protected from salt spray, oil exposure, and environmental wear.

\r\n \r\n - \r\n

Low Downtime Solution – Minimizes project delays and maximizes tool availability.

\r\n \r\n - \r\n

Recommended as Standard Spare Inventory – Essential for heavy-usage descaling operations.

\r\n \r\n - \r\n

Reliable Replacement Under Tough Conditions – Maintains performance under prolonged use.

\r\n \r\n - \r\n

IMPA-Coded for Supply Chain Ease – Simplifies procurement and logistics documentation.

\r\n \r\n - \r\n

Reinforced Chain Compatibility – Accepts standard KP2000E impact chains.

\r\n \r\n - \r\n

Backed by Marine Tooling Standards – Built to match manufacturer design tolerances and quality levels.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Code | 591212 |

| Model | KP1200E |

| Operation Type | Electric (440V, 3-phase, 60 Hz) |

| Cutting Width | 120 mm |

| Impact Rate | 66,000 blows per minute |

| Application | Paint and rust removal from flat or lightly contoured surfaces |

| Safety Feature | Dust-proof protective cover for debris containment |

- \r\n

- \r\n

⚡ Electric-Powered Chain Descaler – Ideal for fast removal of rust, paint, and heavy surface scale.

\r\n \r\n - \r\n

📏 120 mm Cutting Width – Covers a large area per pass for high-efficiency descaling.

\r\n \r\n - \r\n

💥 66,000 Blows Per Minute (BPM) – Delivers rapid surface impact for aggressive material removal.

\r\n \r\n - \r\n

🔌 Operates on 440V, 3-Phase, 60 Hz – Designed for industrial and marine-grade power systems.

\r\n \r\n - \r\n

🧱 Ideal for Flat Surfaces & Spot Scaling – Used on decks, tank tops, hatches, and metal structures.

\r\n \r\n - \r\n

🧰 Dust-Proof Protective Cover – Prevents debris ingress and extends tool life.

\r\n \r\n - \r\n

🔧 Heavy-Duty Build for Shipyard & Industrial Use – Withstands rugged conditions and continuous operation.

\r\n \r\n - \r\n

🧪 Chain Link Head for Surface Impact – Flexible chains adapt to surface texture and remove scale without gouging.

\r\n \r\n - \r\n

🧤 Low-Vibration Performance – Improves operator comfort and reduces fatigue.

\r\n \r\n - \r\n

🛠️ Efficient for Pre-Coating Surface Prep – Ensures clean substrate for adhesion of coatings or primer.

\r\n \r\n - \r\n

✅ IMPA Coded for Standard Marine Procurement – Easily sourced through ship supply networks.

\r\n \r\n - \r\n

🔄 Consistent Output in Long-Duration Jobs – Suitable for prolonged descaling operations without overheating.

\r\n \r\n - \r\n

🧲 Compact for Small-to-Medium Area Treatment – Maneuvers easily across decks or interior surfaces.

\r\n \r\n - \r\n

🌊 Safe for Marine and Industrial Zones – Works in damp, oil-exposed, or open-air environments.

\r\n \r\n

\r\n

- \r\n

- \r\n

🔁 Long-Term Service with Replaceable Chain Links – Easy maintenance and extended equipment lifespan

\r\n \r\n

Impa 591237 Spare Chain Drum for Electric Descaling Machine KP1200E & KP400 – Replacement Part

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Material | Hardened Industrial Steel Or Alloy |

| IMPA Code | 591237 |

| Compatible Models | KP1200E and KP400 electric descaling chain machinesKP1200E and KP400 electric descaling chain machines |

| Function | Replacement chain drum for rust and paint removal tools |

| Use Type | Marine, shipyard, and industrial descaling operations |

| Installation | Drop-in, bolt-on drum with standard fittings |

| Maintenance Support | Enables continued performance with minimal downtime |

- \r\n

- \r\n

🔩 Original Replacement Chain Drum – Specifically designed for KP1200E and KP400 electric descaling machines.

\r\n \r\n - \r\n

⚙️ Ensures Continuous Operation – Reduces downtime by allowing fast replacement during maintenance.

\r\n \r\n - \r\n

🧱 Heavy-Duty Build Quality – Manufactured for long life under high-speed impact conditions.

\r\n \r\n - \r\n

🔄 Compatible with High-Speed Operation – Withstands 66,000 BPM without performance degradation.

\r\n \r\n - \r\n

🧰 Ideal for Shipyard and Industrial Use – Commonly used in rust and paint removal applications.

\r\n \r\n - \r\n

🔧 Drop-In Replacement Design – Easily mounts into KP1200E or KP400 machines without modification.

\r\n \r\n - \r\n

📦 Supplied Individually or in Bulk – Supports ongoing operations or fleet-wide maintenance needs.

\r\n \r\n - \r\n

🧪 Corrosion-Resistant Materials – Withstands exposure to rust, debris, and harsh environments.

\r\n \r\n - \r\n

🌊 Marine and Industrial Grade – Engineered for use in shipyards, dry docks, and offshore vessels.

\r\n \r\n - \r\n

🛠️ Reliable Surface Prep Tool Accessory – Essential for maintaining optimal tool performance.

\r\n \r\n - \r\n

✅ IMPA Coded for Easy Procurement – Standardized listing under marine supply chain systems.

\r\n \r\n - \r\n

🔗 Compatible with Descaling Chains – Accepts factory-specified chain links and configurations.

\r\n \r\n - \r\n

🧲 Safe to Use at Full Rated Speeds – Designed to perform under standard 440V descaling equipment loads.

\r\n \r\n - \r\n

🔁 Interchangeable Between Models – Supports both KP1200E and KP400 series tools.

\r\n \r\n - \r\n

🧤 Easy Handling for On-Site Replacement – Can be changed by crew with basic tools.

\r\n \r\n

Impa 591661 Pneumatic Piston Pump – High-Efficiency Drum Pump for Lubrication & Viscous Liquid

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Code | 591661 |

| Pump Type | Pneumatic piston-type |

| Drum Compatibility | 200L (standard drum) |

| Material | Aluminium / stainless steel body |

| Fluid Compatibility | Oil, lubricant, light fuel, additives |

| Operating Pressure Range | 4–8 bar (58–116 psi) |

| Marine Suitability | Yes – oil tanks, drums, lube systems |

- \r\n

- \r\n

💧 High-Efficiency Fluid Transfer – Specially designed for pumping oil, grease, and other viscous liquids.

\r\n \r\n - \r\n

💨 Air-Driven Piston Mechanism – Spark-free pneumatic operation, safe for flammable or ATEX-classified areas.

\r\n \r\n - \r\n

🛢️ Ideal for Drums & Barrels – Standard configuration fits 200L oil drums and other industry barrels.

\r\n \r\n - \r\n

⚙️ Automatic Operation for Lubrication Systems – Works seamlessly with onboard or industrial lube circuits.

\r\n \r\n - \r\n

🔧 Corrosion-Resistant Build – Stainless/aluminium construction ideal for harsh marine and chemical conditions.

\r\n \r\n - \r\n

🧩 Compact & Durable Design – Easy to transport and install with long service life.

\r\n \r\n - \r\n

🧰 Seamless Finish Reduces Contamination Risk – Ensures smooth, uncontaminated fluid delivery.

\r\n \r\n - \r\n

🔁 Low Maintenance Requirements – Minimal moving parts with reduced wear and easy servicing.

\r\n \r\n - \r\n

🧪 Compatible with Multiple Fluids – Works with oils, lubricants, light fuels, additives, and similar substances.

\r\n \r\n - \r\n

📏 Consistent Discharge Volume Per Stroke – Maintains accuracy for batch filling or measured dispensing.

\r\n \r\n - \r\n

🧲 No Electrical Power Needed – Operates solely on air pressure for safety and portability.

\r\n \r\n - \r\n

🚫 Explosion-Proof for Fuel & Solvent Zones – Reliable performance in hazardous tank areas or drum stations.

\r\n \r\n - \r\n

🧱 Fine Finish Internals – Prevents fluid contamination and ensures purity during fluid movement.

\r\n \r\n - \r\n

✅ Approved for Industrial & Marine Use – Standard equipment for ship engine rooms and refineries.

\r\n \r\n - \r\n

📦 Comes Ready-to-Use with Mounting Accessories – Plug-and-pump setup for onboard or warehouse drums.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Codes | 591021 (110V, 4") |

| Tool Type | Electric angle grinder |

| Disc Sizes | 4", 5", 7" |

| Voltage Options | 110V and 220V |

| Motor Type | High-speed, air-cooled electric motor |

| Use Compatibility | Suitable for marine, offshore, shipyard, and industrial tasks |

- \r\n

- \r\n

⚡ Electric-Powered for Versatile Operation – Suitable for cutting, grinding, and surface preparation tasks.

\r\n \r\n - \r\n

🔌 Available in 110V and 220V Models – Compatible with different onboard and industrial power systems.

\r\n \r\n - \r\n

📏 Multiple Disc Sizes for Different Applications – Choose from 4\\\", 5\\\", and 7\\\" based on material and task.

\r\n \r\n - \r\n

🔧 IMPA-Coded Variants for Easy Sourcing –

\r\n

• 110V: 4\\\" (IMPA 591021), 5\\\" (IMPA 591022)

• 220V: 4\\\" (IMPA 591031), 5\\\" (IMPA 591032), 7\\\" (IMPA 591034) \r\n - \r\n

🛠️ Ergonomic Grip & Lightweight Design – Improves user control and comfort during extended use.

\r\n \r\n - \r\n

🧱 High-Torque Motor for Industrial Use – Cuts through metal, concrete, or coated surfaces with ease.

\r\n \r\n - \r\n

🧲 Dust-Resistant Ventilation Ports – Protects internal components and extends tool life.

\r\n \r\n - \r\n

🧰 Suitable for Cutting, Grinding & Polishing Discs – Compatible with abrasive wheels, wire brushes, and sanding pads.

\r\n \r\n - \r\n

🧤 Side Handle for Two-Handed Operation – Enhances safety and stability during precision work.

\r\n \r\n - \r\n

🔄 High RPM Output – Ensures smooth and fast material removal or cutting action.

\r\n \r\n - \r\n

📦 Supplied with Guard & Wrench – Ready-to-use with included safety accessories.

\r\n \r\n - \r\n

🔋 Efficient Power Consumption – Engineered for continuous use without overheating.

\r\n \r\n - \r\n

✅ IMPA-Listed for Global Marine Supply Compliance – Streamlines tendering and sourcing processes.

\r\n \r\n - \r\n

🧪 Rugged Housing for Marine & Industrial Environments – Designed to withstand vibration and surface debris.

\r\n \r\n

\r\n

- \r\n

- \r\n

🔁 Available with Spare Brushes and Accessories (On Request) – Ensures long-term operational support.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Codes | 232516 (Standard) |

| Contents | Absorbent pads, socks, disposal bags, PPE (optional), instruction manual |

| Absorbent Type | Oil-only polypropylene – hydrophobic |

| Container Type | Bag, plastic drum, or mobile bin |

| Deployment Speed | Immediate – pre-packed and portable |

| Spill Capacity Range | Varies by kit (small to large spills) |

| Application Use | Marine, industrial, logistics, fuel stations, transport |

- \r\n

- \r\n

🧰 Complete Spill Response Kit – Contains all essential components for rapid oil spill containment and cleanup.

\r\n \r\n - \r\n

🛢️ High-Absorbency Materials – Includes pads, socks, and booms made of polypropylene to absorb oil while repelling water.

\r\n \r\n - \r\n

🚨 Available in 3 Configurations – Standard bag (IMPA 232516), Plastic Drum (IMPA 232531), and Wheelie Bin (IMPA 232532).

\r\n \r\n - \r\n

♻️ Pre-Packed for Emergency Deployment – Enables immediate spill response without the need for assembly.

\r\n \r\n - \r\n

🌊 Marine-Grade Oil-Only Absorbents – Specifically designed to float and absorb hydrocarbons on water surfaces.

\r\n \r\n - \r\n

🧱 Absorbent Socks (Sausages) – Wrap around the spill area to prevent spreading and contain leakage effectively.

\r\n \r\n - \r\n

📄 Includes Instruction Manual – Provides step-by-step guidance on proper spill control and disposal procedures.

\r\n \r\n - \r\n

🧤 Optional PPE Included – Gloves and protective gear available for safe cleanup handling in hazardous conditions.

\r\n \r\n - \r\n

📦 Comes in Durable Containers – Kits are housed in carry bags, drums, or mobile wheelie bins based on size and use-case.

\r\n \r\n - \r\n

🚛 Wheelie Bin Kit Ideal for Large Spills – Designed for mobile deployment in busy industrial or port zones.

\r\n \r\n - \r\n

🧪 Oil-Selective – Does Not Absorb Water – Perfect for use on marine decks, wet industrial floors, and docks.

\r\n \r\n - \r\n

✅ Conforms to Environmental Compliance Requirements – Supports MARPOL and spill response regulation mandates.

\r\n \r\n - \r\n

🧲 Lightweight, Non-Toxic & Non-Reactive Materials – Safe for workers and suitable for indoor/outdoor use.

\r\n \r\n - \r\n

🔁 Disposable Components with Minimal Residue – Simplifies cleanup and ensures eco-friendly disposal.

\r\n \r\n - \r\n

📊 Customizable Kits Available on Request – Contents and capacity can be tailored to specific operational needs.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| IMPA Code | 591251 |

| Operation Type | Pneumatic (compressed air-driven) |

| Mounting Style | Trolley-mounted |

| Usage | Removal of paint, rust, scale, and chemical coatings |

| Cutter System | Quick-change disc/cutter assembly |

| Use Environment | Marine, shipyard, offshore, and industrial maintenance |

| Surface Type | Steel, coated metal, concrete |

- \r\n

- \r\n

Heavy-Duty Pneumatic Scaling System – Designed for aggressive removal of rust, paint, scale, and coatings.

\r\n \r\n - \r\n

Trolley-Mounted Design – Enhances mobility and reduces operator fatigue during extended use.

\r\n \r\n - \r\n

Air-Powered Operation – Provides high-impact force for industrial-grade surface preparation.

\r\n \r\n - \r\n

Quick-Change Cutter System – Allows fast replacement of cutters to minimize downtime and increase efficiency.

\r\n \r\n - \r\n

Built for Large-Area Surface Prep – Ideal for decks, hulls, tanks, and structural components.

\r\n \r\n - \r\n

Durable Frame & Components – Withstands rough handling in shipyards and industrial environments.

\r\n \r\n - \r\n

Consistent Impact Performance – Maintains uniform surface removal even in extended operation cycles.

\r\n \r\n - \r\n

Low Maintenance Requirements – Fewer moving parts and robust construction ensure long-term reliability.

\r\n \r\n - \r\n

Safe for Marine & Industrial Use – Operates without sparks or electricity, suitable for flammable or wet zones.

\r\n \r\n - \r\n

Compatible with Shipyard Air Supply Systems – Standard pneumatic input for ease of integration.

\r\n \r\n - \r\n

Efficient on Steel, Concrete, and Coated Surfaces – Versatile across multiple substrate types.

\r\n \r\n - \r\n

High Output for Speedy Project Completion – Reduces time spent on scaling and cleaning operations.

\r\n \r\n - \r\n

Integrated Dust/Scale Deflection – Helps manage debris and improve working conditions.

\r\n \r\n - \r\n

Operator Control Handle with Grip – Improves guidance and safety during operation.

\r\n \r\n

\r\n

- \r\n

- \r\n

IMPA-Coded for Procurement Compliance – Streamlines sourcing through standardized marine supply chains.

\r\n \r\n

| Business Type | Supplier, Retailer, Trader, Distributor, Importer |

| Material | Ductile Iron Or Stainless Steel With Anti-corrosive Coating |

| Type | Viking Johnson Type Flexible Pipe Coupling |

| Connection Type | Plain-end pipe to plain-end pipe |

| Seal Type | Elastomeric pressure gasket seal (EPDM/NBR available) |

| Pipe Compatibility | Steel, PVC, ductile iron, GRP |

| Installation | Bolt-tightened, no welding required |

| Use Environments | Marine, industrial, offshore, municipal, HVAC |

- \r\n

- \r\n

🔧 Flexible Coupling for Plain-End Pipes – Joins pipes securely without flanges or threads, allowing axial and angular movement.

\r\n \r\n - \r\n

💧 Leak-Proof Pressure Seal – Incorporates a resilient gasket to maintain a watertight seal under varying pressures and vibrations.

\r\n \r\n - \r\n

🔩 Ideal for High-Pressure Systems – Engineered to withstand demanding pressure applications in marine and industrial sectors.

\r\n \r\n - \r\n

🧱 Compensates for Misalignment & Thermal Expansion – Accommodates small shifts or thermal elongation in connected pipelines.

\r\n \r\n - \r\n

⚙️ Constructed from Corrosion-Resistant Materials – Body typically made of ductile iron or stainless steel for long-term durability.

\r\n \r\n - \r\n

🧰 Quick & Simple Installation – No welding, threading, or special tools required – reduces labor time and costs.

\r\n \r\n - \r\n

🔧 Double Bolt or Flanged Types Available (Customizable) – Designed to fit a wide range of pipe diameters and conditions.

\r\n \r\n - \r\n

🧪 Suitable for Various Pipe Materials – Works with steel, ductile iron, PVC, and GRP pipes.

\r\n \r\n - \r\n

🌊 Marine & Offshore Grade – Performs reliably in seawater environments and shipboard piping systems.

\r\n \r\n - \r\n

🔁 Reusable & Easy to Maintain – Can be disassembled and reinstalled during pipeline modifications.

\r\n \r\n - \r\n

🔥 Temperature and Pressure Rated for Safety – Manufactured to industry standards for pressure containment and thermal tolerance.

\r\n \r\n - \r\n

🛠️ Compact & Space-Efficient Design – Ideal for confined spaces where flanged joints may not be feasible.

\r\n \r\n - \r\n

✅ Vibration Damping Function – Helps minimize pipe stress and noise in dynamic systems.

\r\n \r\n - \r\n

🧲 Compliant with Industry Standards – Typically conforms to BS, ISO, or EN standards (based on model).

\r\n \r\n - \r\n

📦 Available in Multiple Sizes & Pressure Ratings – Customization possible for diameter, pressure class, and material grade.

\r\n \r\n